Parts of the Loom #

Understanding the structural possibilities of woven cloth depends on a deep understanding of the processes by which woven cloth is assembled. While, as Albers writes, “Any weaving, even the most elaborate, can be done, given time, with a minimum of equipment” [1], we focus on a class of equipment used primarily in industry and western weaving style: the horizontal or two-beam weaving loom. This is slightly different, but not incompatible with tapestry weaving, which is a more free-hand process.

After this lesson, you should be able to:

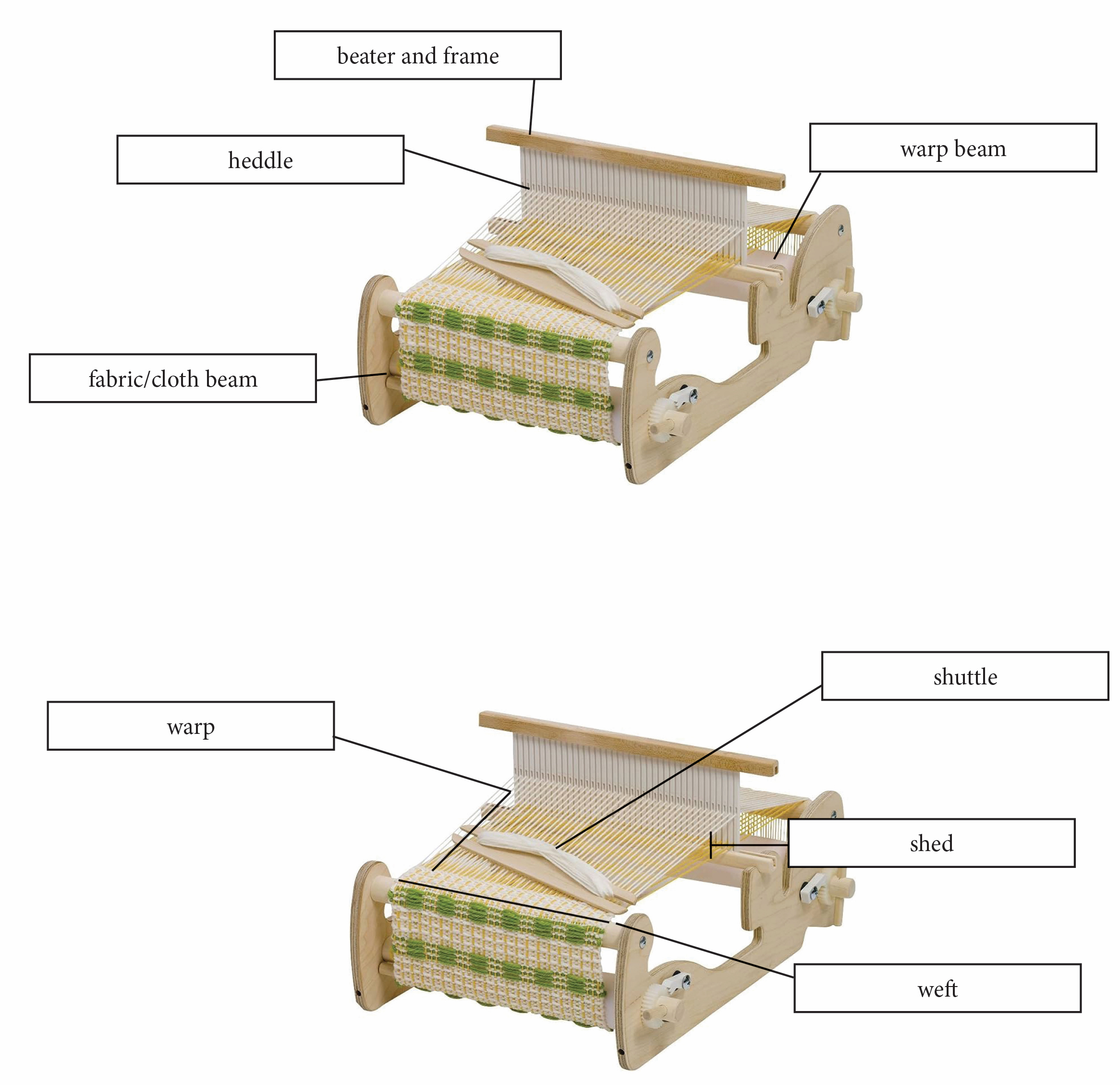

- identify these parts of a loom:

- warp beam

- fabric/cloth beam

- heddles

- reed

- beater

- define the following steps in the weaving process

- open a shed

- throw weft

- beat / pack

- define the following terms:

- shuttle

- pick

- end

- frame

- treadle

Parts to Know #

The looms we will be working with all have the following parts, albeit in sometimes different configurations: warp beam, fabric/cloth beam, heddles, reed, beater. The warp is tensioned across the two beams and in its path from warp beam to fabric/cloth beam, it travels through the heddles and reed (which is usually held within the) beater. A single yarn within the warp is called an end.

Rigid Heddle Loom #

A rigid heddle loom has a preset relationships between the heddles embedded into its structure, making it optimized to weave one structure, tabby, very quickly. This also allows it to use the frame for both selecting heddles and as the beater/reed.

A rigid heddle loom has a preset relationships between the heddles embedded into its structure, making it optimized to weave one structure, tabby, very quickly. This also allows it to use the frame for both selecting heddles and as the beater/reed.

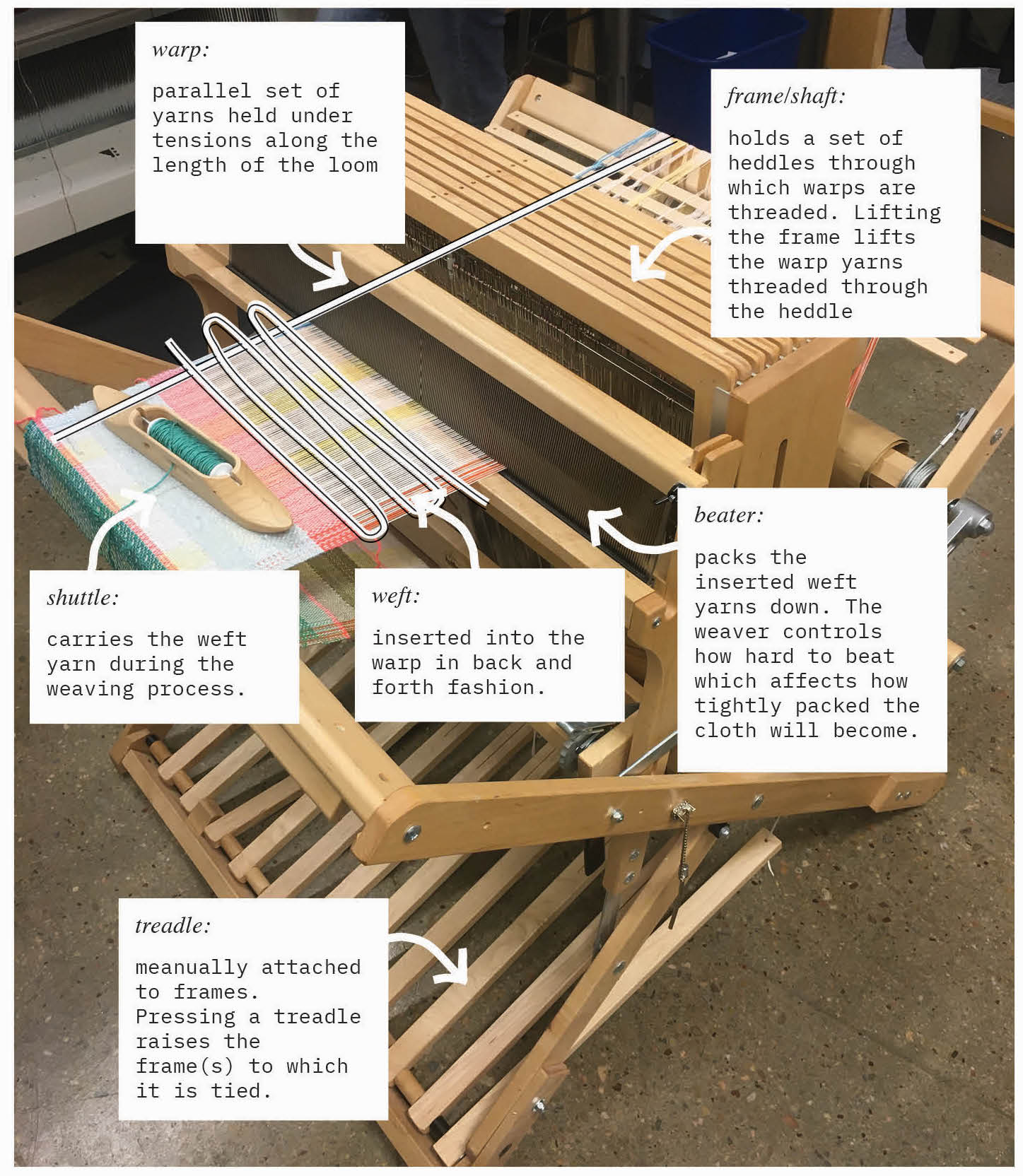

Floor Loom Parts #

A floor loom or harness loom allows the weaver to specify the relationship between frames and pattern by manually threading the heddles on select frames with select warps. While weaving, the weaver can control which warp ends are selected by lifted combinations of frames (either by hand as on a direct tie loom or via treadles, as on a floor loom). A separate beater, and within the beater, a reed, are used to beat the weft after each insertion.

Weaving Process #

The process of weaving follows these general steps.

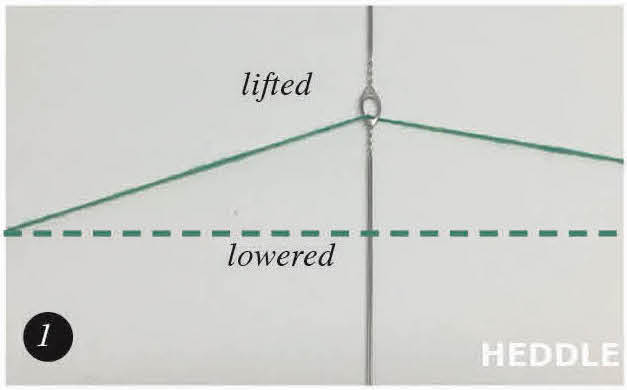

- The weaver opens a shed by raising a selection of warp ends. On your paper loom, you did this by hand. On a computerized jacquard loom, a bitmap image tells the machine which heddles to raise and lower just like you used the black and white cells to determine what to lift or not.

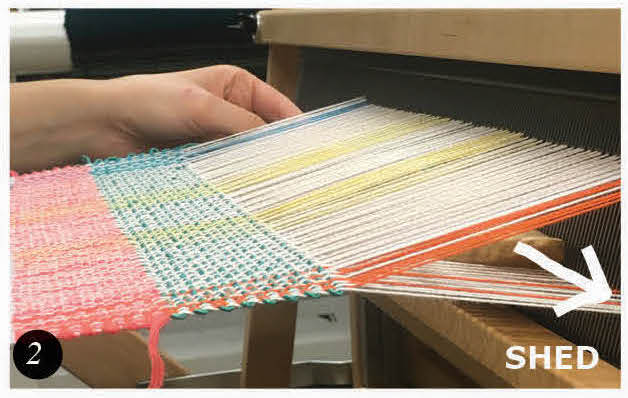

- When heddles are lifted, they raise the warp threads that are threaded through them and create a SHED, which is the term for the space between the raised and lowered warp threads.

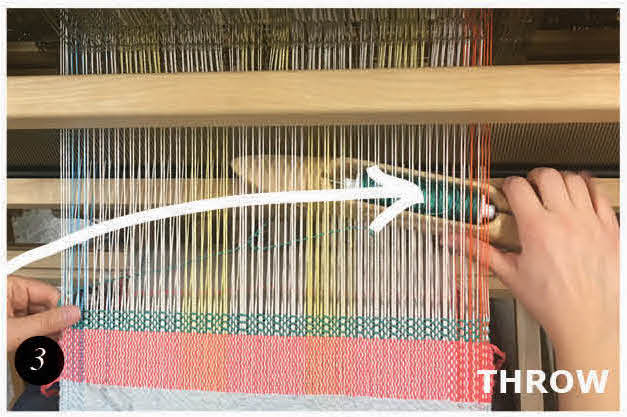

- A SHUTTLE carries the weft thread and is THROWN through the shed, adding a weft row, or PICK, to the cloth.

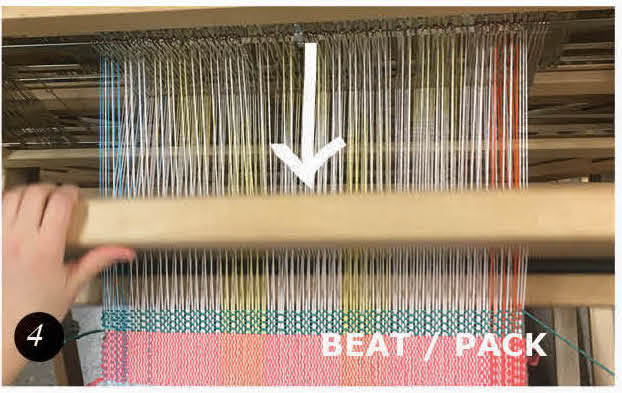

- A weaver closes the shed (lowers all warps) and BEATS, pressing the new weft on top of the previous weft. This pressing PACKS the weft yarns in the weave

Citations #

[1] Anni Albers. 1974. Anni Albers : On Weaving. Wesleyan, Middletown (Conn.).

Additional Resources #

Deborah Chandler’s overview of different looms, loom parts, and weaving mechanics.